Sepro Launches Packaged Robot Solutions for Medical and Pharmaceutical Applications

To meet growing demand for automation in clean rooms and other sensitive environments in medical and pharmaceutical molding plants, Sepro Group is introducing the MED Series of 3-, 5- and 6-axis robots.

These packaged units come ready-equipped with the design and operational features that medical customers have been requesting on over 1500 molding machines sold in recent years for ISO 7 and 8 clean room applications. These features ensure clean operation as well as high precision and continuous productivity.

“Sepro robots increase productivity and enhance workflows” explains Claude Bernard, Product Marketing Director for Sepro. “Within the clean room market, our robots can be used across the entire production line – from assembly to inspection, traceability and packaging.”

The Swiss molding company, Fischer & Söhne, which produces medical and pharmaceutical products, uses Sepro robots in its clean rooms. CEO Iwan Tresch says: “With production based on the food industry standard BRC, hygiene and clean room requirements, no compromise is possible. With Sepro robots, we can increase our productivity while guaranteeing an optimal level of hygiene. Sepro is a responsive company, with fast delivery times and flexibility.”

In general, the Sepro MED robots include FDA-approved lubrication on all linear guiding surfaces and gearing. Cables can be protected in conduits and all robot surfaces are smooth, painted medical white with limited decoration so that dust does not accumulate, making cleaning easier. Only clean materials are used in many components – like end-of-arm tooling — that come into contact with the molded parts. Places where grease or other lubrication is used are enclosed so that none can escape into the molding area. 5X MED robots include a two-axis servo wrist to provide a total of five numerically controlled axes of motion. S5 Line MED robots have three servo-driven axes and a pneumatic wrist. All robots can be optionally equipped with pneumatic filtration to 0.3 micron.

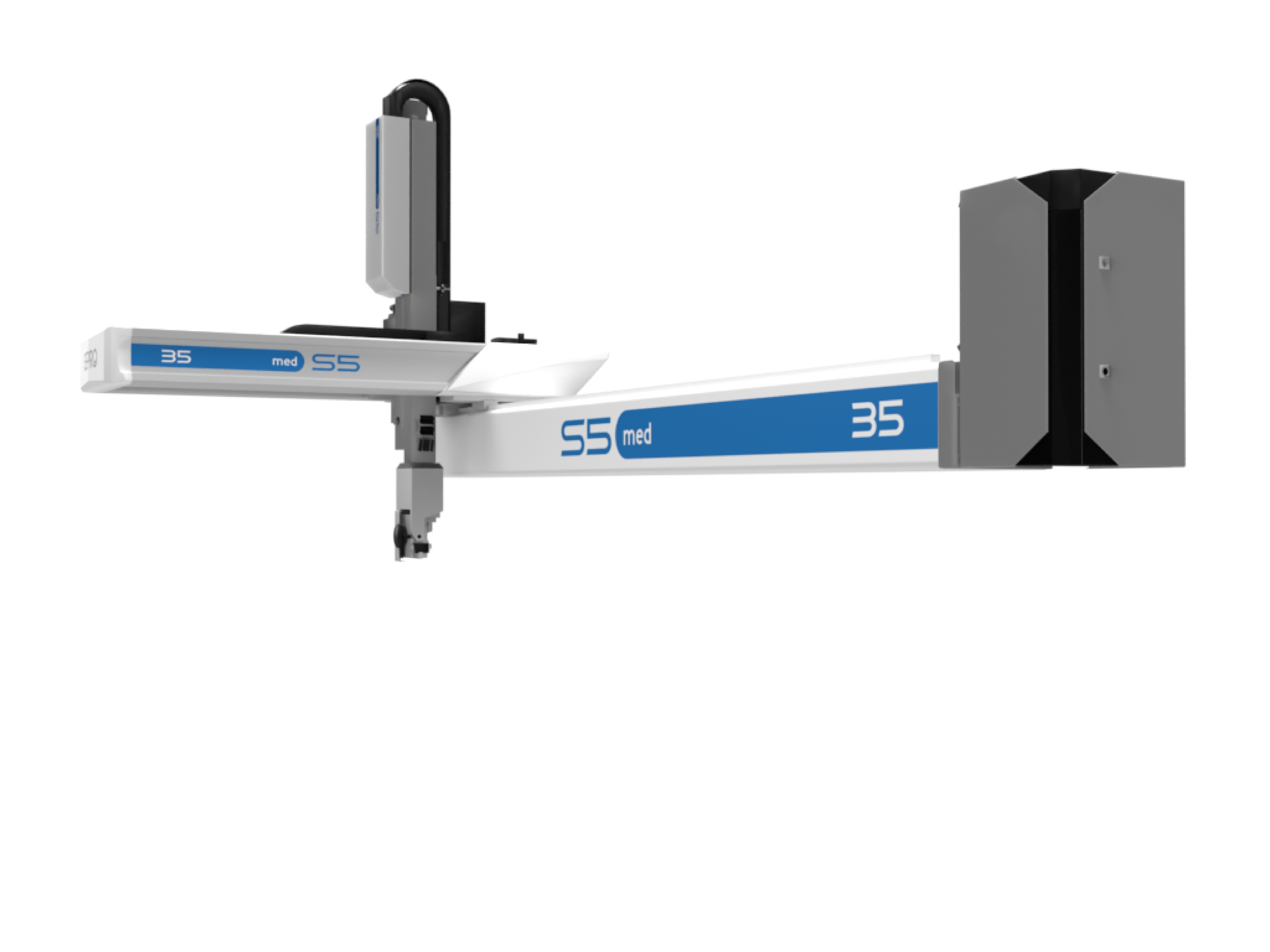

CARTESIAN BEAM ROBOTS

The 5X MED and S5 Line MED ranges each include robots in three different sizes to allow them to serve molding machines with from 30 to 800 tons of clamping force. Nominal payload capacity (part plus end-of-arm tooling) ranges from 5 to 20 kg (11 to 44 lb.). The robots can be installed in a conventional transverse or space-saving axial layout. Available stroke lengths are as follows:

| S5/5X 15 MED | S5/5X 25 MED | S5/5X 35 MED | ||

| Horizontal (X) | mm (in) | 1500 – 4000 (59 – 157) | 1500 – 6000 (59 – 236) | 2000 – 9000 (79 – 354) |

| Demolding (Y) | mm (in) | 500 (20) | 700 (28) | 900 (35) |

| Vertical (Z) | mm (in) | 1000 (39)* | 1400 (55)** | 1800 (71)** |

* Direct Arm

** Telescopic Arm

6-AXIS ROBOTS COMPLY WITH ISO 5

Offered in collaboration with Stäubli Robotics, the Sepro 6X MED 6-axis-servo articulated-arm robots are inherently clean. The standard Staubli arms are certified for ISO 5 (Class 100) clean rooms without modification. However, the smooth, clean white surfaces make keeping them clean just that much easier. In fact, the 6X MED robots can exceed the level of cleanliness possible with injection-molding processes.

6-axis robots are typically floor mounted (but can be ceiling-mounted) and usually enter the molding machine from the side. Laminar air flow allows these installations to meet the requirements of ISO 7 and 8.

Four models are available to serve molding machines from 20 to 1300 tons.

| 6X-60 MED | 6X-90 MED | 6X-160 MED | 6X-200 MED | ||

| 360⁰ Reach

Long Arm Version |

mm (in) | 670 (26)

920 (36) |

1200 (47)

1450 (57) |

1710 (67)

2010 (79) |

2194 (86)

2594 (102) |

| Payload | kg (lb) | 3.5 (7.7)

2 (4.4) |

6 (13.2)

5 (11) |

20 (44)

14 (30.8) |

100 (220)

60 (132) |

In addition to 3-, 5- and 6-axis MED robots, Sepro also supplies a wide range of peripheral and downstream equipment, including end-of-arm tooling, safety guarding, conveying systems, part inspection and part separation. “Solution by Sepro” is also available to integrate multiple robots, specialized end-of-arm tooling, plus a variety of feeders (bowl, drawer or manual), , cavity separation, degating/trimming, box filling and other equipment – all customized to suit specific manufacturing objectives.

Download and read the full press release below.

Download Text Documents

Download Photos