Sepro Group Robots on Display at Fakuma 2021

Observing all appropriate Covid-19 protocols, Sepro Group will bring a total of 11 robots to Fakuma 2021, which is scheduled for 12 – 16 October in Friedrichshafen, Germany. Seven of those robots will be displayed on Sepro’s own stand (Hall A1, booth 1203) and two of those will be shown on injection-molding machines operating in the booth. A further 4 units will be demonstrated on machines being displayed by IMM manufacturers in partnership with Sepro.

Observing all appropriate Covid-19 protocols, Sepro Group will bring a total of 11 robots to Fakuma 2021, which is scheduled for 12 – 16 October in Friedrichshafen, Germany. Seven of those robots will be displayed on Sepro’s own stand (Hall A1, booth 1203) and two of those will be shown on injection-molding machines operating in the booth. A further 4 units will be demonstrated on machines being displayed by IMM manufacturers in partnership with Sepro.

“Sepro is pleased that shows are back on track after last year’s cancelation of the 2020 Fakuma edition” said Charles de Forges, CEO of Sepro Group, “and we have a strong story to tell. Our exhibit will present 3-, 5- and 6-axis robots that are part of the most extensive portfolio in the industry, which also includes comprehensive range of peripheral equipment. Whatever project you may be working on, large or small, complex or simple pick-and-place, you will find that Sepro has a perfect solution for you.”

Sumitomo-Demag, Sepro’s longest standing OEM partner, is providing one of the two molding machines that will be in operation during the show. The 130-ton press will be molding an automobile gearstick baseplate that will be removed from the mold by an SDR 11 robot, the Sumitomo-Demag equivalent of the Sepro Success 11.

Elsewhere on the stand, a Haitian Zeres 60-ton electric IMM will be equipped with Sepro’s smallest Success robot, the Success 5, which will be producing a ‘cleankY’ hygienic door opening tool.

Other robots being demonstrated in the Sepro booth include:

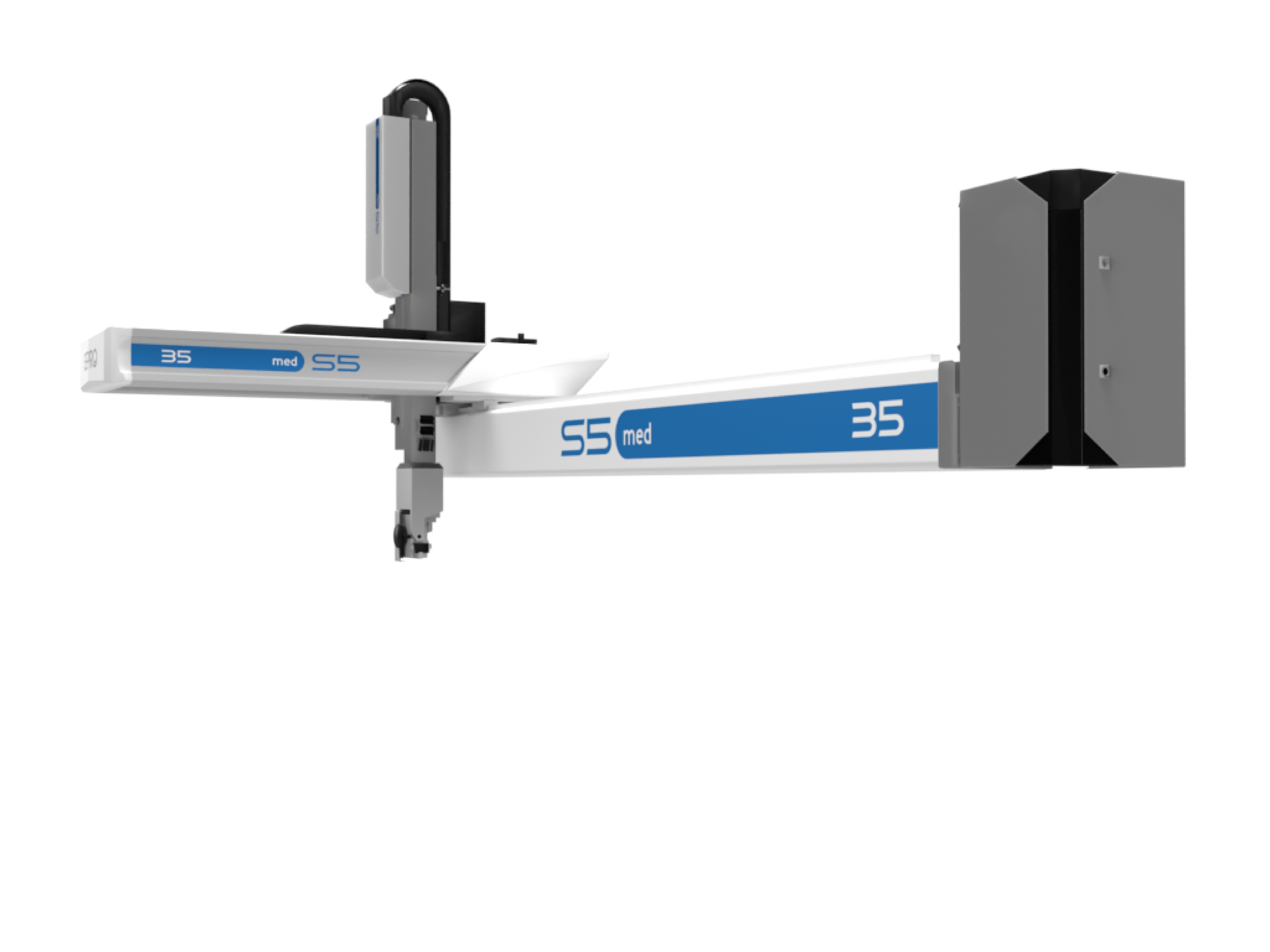

- S5-25 MED, a 5-axis robot recently introduced for medical applications. It will be manipulating a medical component from the Swiss molder Fischer Soehne AG.

- Nearby, a Success 22X, the redesigned 5-axis version of Sepro’s best-selling robot range, will be handling a BMW Series 2 automobile grill.

- A smaller, 3-axis Success 11 will be working with VW hubcap logos.

- An S5 picker, a 3-axis servo-driven sprue picker will be simulating sprue picking operations.

- A 6X-140, a small 6-axis articulated arm robot made in collaboration with Yaskawa Motoman, will be holding a car bumper

Elsewhere on the show, the injection-molding machine manufacturers demonstrating Sepro robots are:

- DECKERFORM Technologies GmbH TOYO, Booth A6-6413

- Ferromatik Milacron GmbH, Milacron LLC, Booth B3-3292

- FANUC Deutschland GmbH, Booth B3-3211

- BILLION SAS, Booth B3-3104

Download and read the full press release below.

Download Text Documents

Download Photos

Back to Press Releases

owing the recent guidelines established by the French government in response to the current rebound of COVID-19, Sepro Group is maintaining its momentum and is open and fully operational, says Xavier Lucas, Chief Sales Officer.

owing the recent guidelines established by the French government in response to the current rebound of COVID-19, Sepro Group is maintaining its momentum and is open and fully operational, says Xavier Lucas, Chief Sales Officer.